How We Solved It

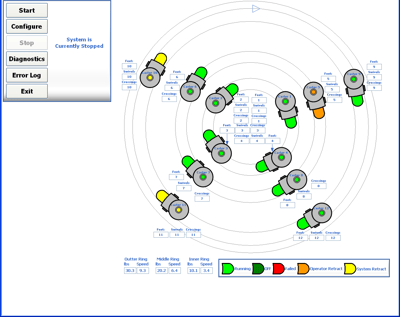

The DSA solution had multiple advantages and upgrades over the Customer’s current system. First, DSA’s design was a large, rotating, automated system which could test up to 12 casters at a single time. The large, circular plate on which the casters rotated around more accurately replicated the use conditions of the casters than the customer’s previous test system. Their previous dynamometer system had a cylindrical contact area while the DSA system utilized a flat diamond coated plate, which included “bumps” to induce shock and vibrations. The DSA system also could variably set the motor speed and independently control the force on each caster via hydraulics, all depending on what kind of test was being done.

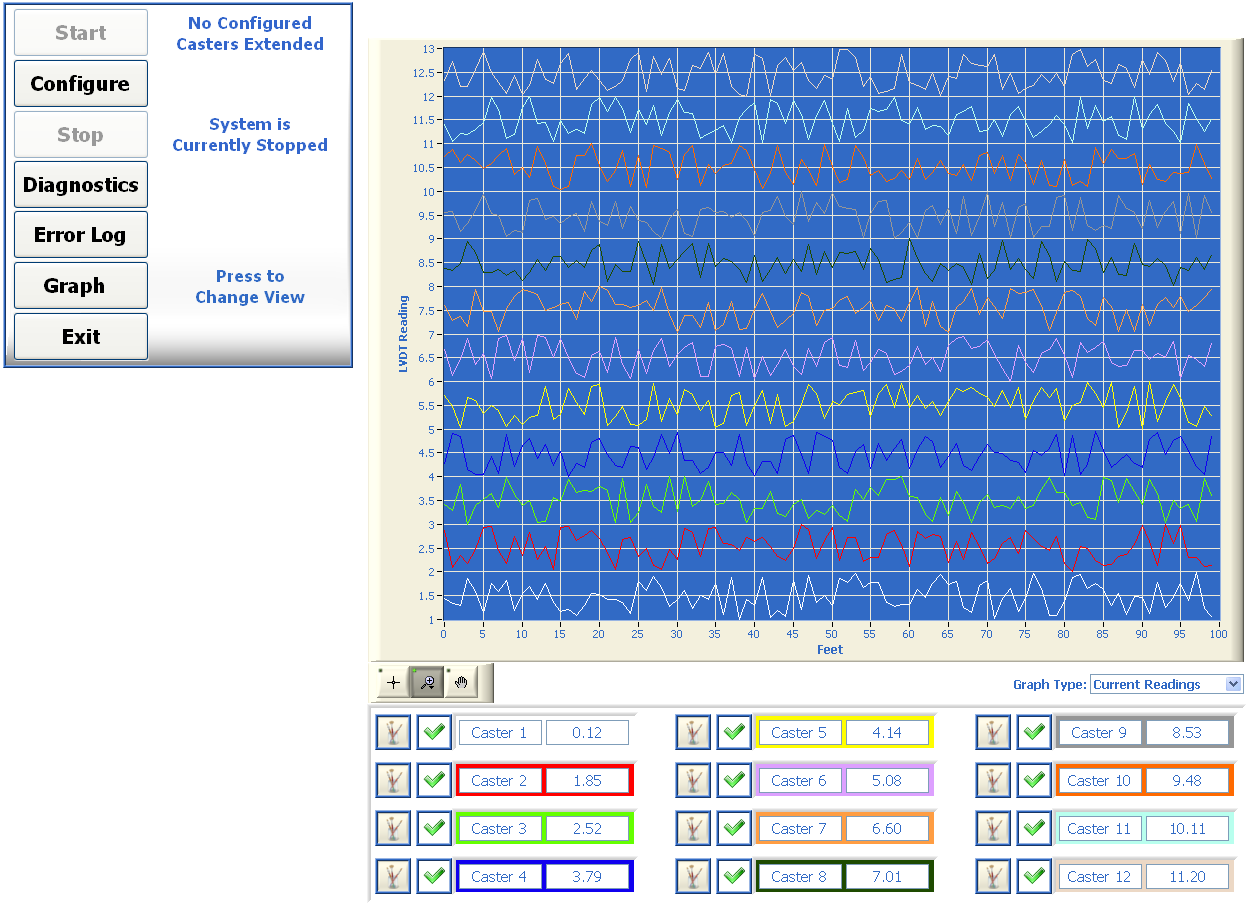

The DSA tester automatically records the speed and the distance travels for each caster. It is also able to detect when a caster has failed, using precise LVDTs. If a caster does fail, the test will stop and save data for any casters that didn’t fail, allowing the operator to replace the failure caster and resume testing. The LabVIEW user interface displays all of the detailed information and status for each caster.