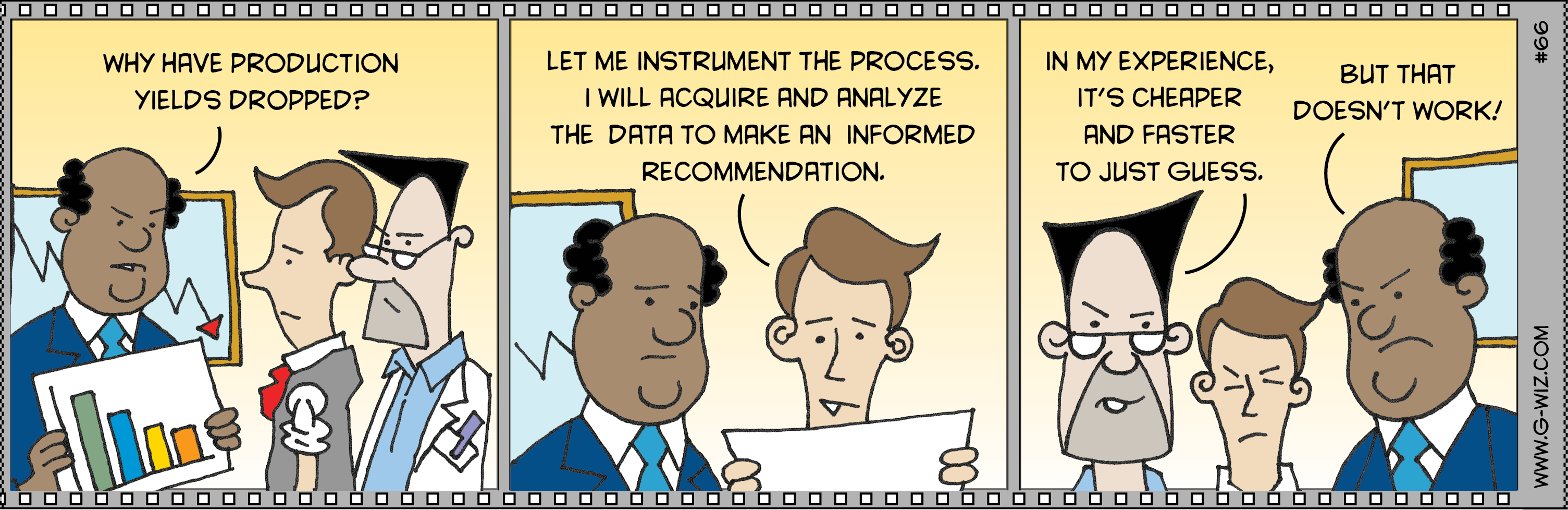

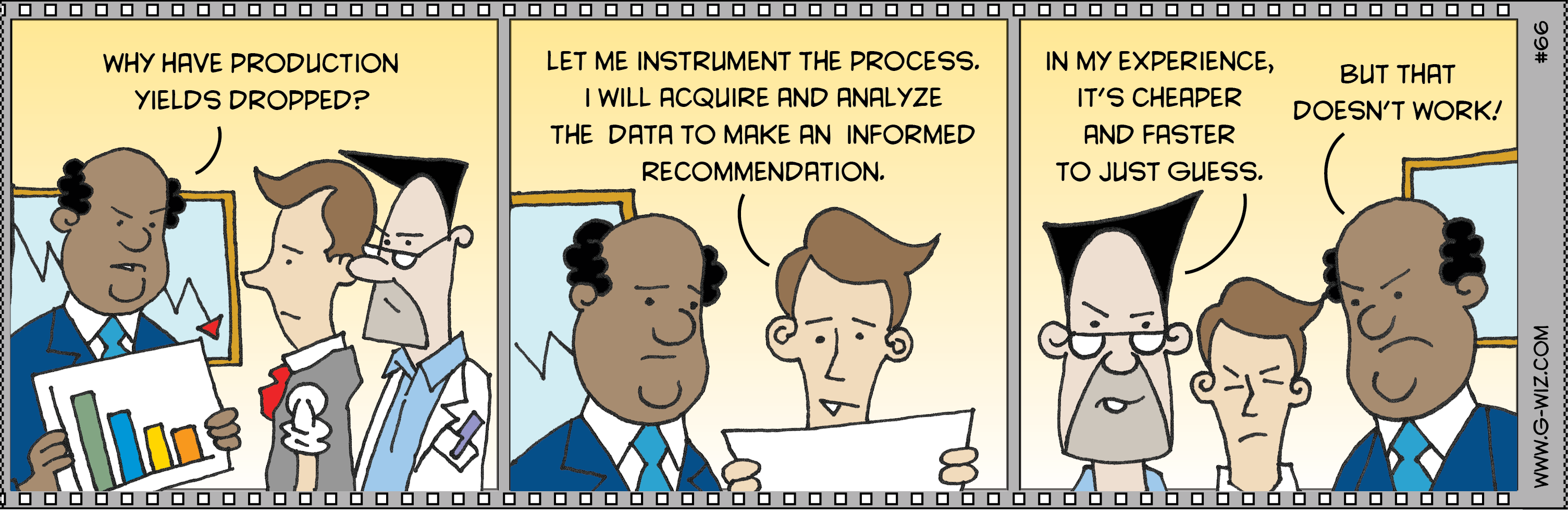

The statement that stands out to me here is by understanding the process it can lead to making more informed changes that will help optimize the end result.

There are many variables in any production line that can cause less than desirable turn outs in the end product. By monitoring key points within the process the data can help provide insight to where things may be deviating from the optimal settings, or help pinpoint the issues origin. By finding out what is truly going on in your process, the data can enable you to make changes ultimately reducing the amount of defects. Additionally, it can also reduce the amount of rework time after the production run. With the correct data analysis seemingly small problems can be uncovered and rectified to optimize your production line saving you time and money.

Are you ready to find and correct the issues that hold you back from your success? Call 724.942.6330 and close the loop.