Integrated & Efficient Automation Solutions

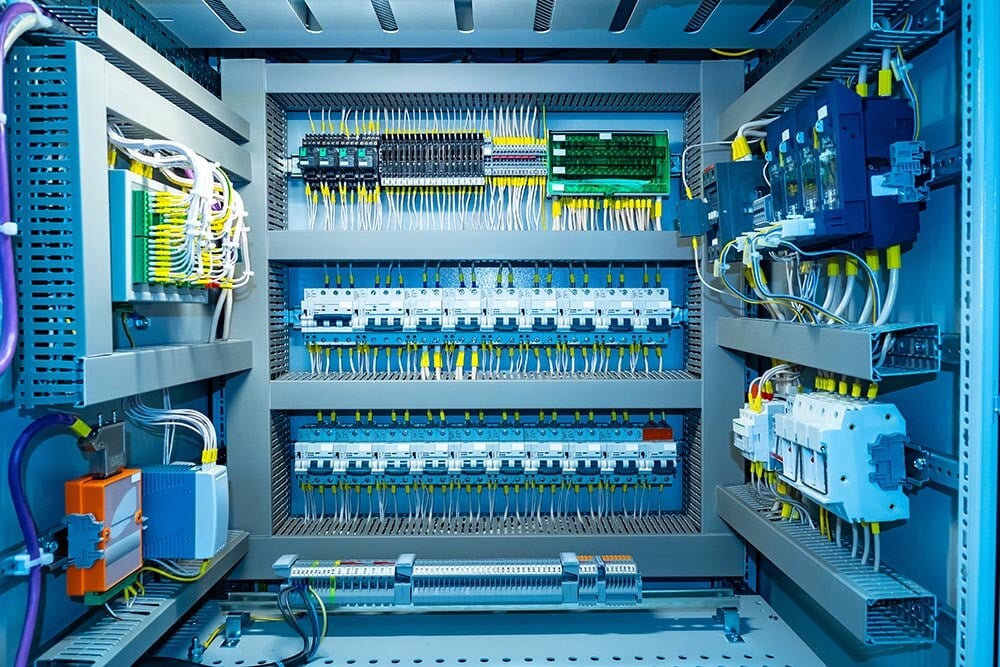

We specialize in providing tailored solutions to address your critical industrial challenges. Our expertise lies in empowering you with top-tier control mechanisms, whether it's implementing PID, fuzzy logic, or cutting-edge neural network control algorithms. Safety is paramount, and we've got you covered with foolproof shutdown execution even when monitoring personnel are unavailable. If you're seeking seamless diagnostics and intuitive plant navigation, our state-of-the-art SCADA applications replicate your process, offering insights and ease like never before.

Measure and

Control

Performance

Consistently Measure

Archive & Control Performance Characteristics

Automate with Reliability

Test and Maintain Processes for Maximum Performance

DSA is a Process Control & Industrial Automation specialist that has pioneered adaptive automation principles, earned advanced industry certifications, offers geographic proximity, guarantees technical breadth and depth, and invests in client empowerment to minimize your risk and vendor dependence.

Process Control & Industrial Automation is absolutely essential in process and discrete manufacturing facilities from oil & gas to chemicals and from nuclear power to robotics.

What We Perfect

Manufacturing Automation

Factory Automation

Smart Manufacturing

Machine Condition Monitoring

PAC & PLC

MMI & HMI & SCADA

MES & MOM

SPC & OEE

Automated Assembly

Automated Inspection

Material Handling

Inventory Tracking

NI/Emerson

Rockwell/Allen-Bradley

Ignition

Industrial Ethernet

PID Control

Robotics

OPC UA

DFM - Design For Manufacturing

Self-Qualification Form

As a technical user, you may know exactly what you need from us already. If you do, save time and streamline the discovery process with our self-qualification form, where you can let DSA know exactly what you need.

Get Started Today

In the realm of Process Control & Industrial Automation, we streamline five key components known as SCADA: sensors/actuators/transducers, I/O devices, controllers, HMI, and a robust database. Our consulting optimizes each factor to create cost-effective solutions. From small-scale labs to large-scale industries, our technology ensures flawless operations and maximized efficiencies. Experience the potential beyond error-free processes.

Would you like one of our experts to contact you to discuss your application?